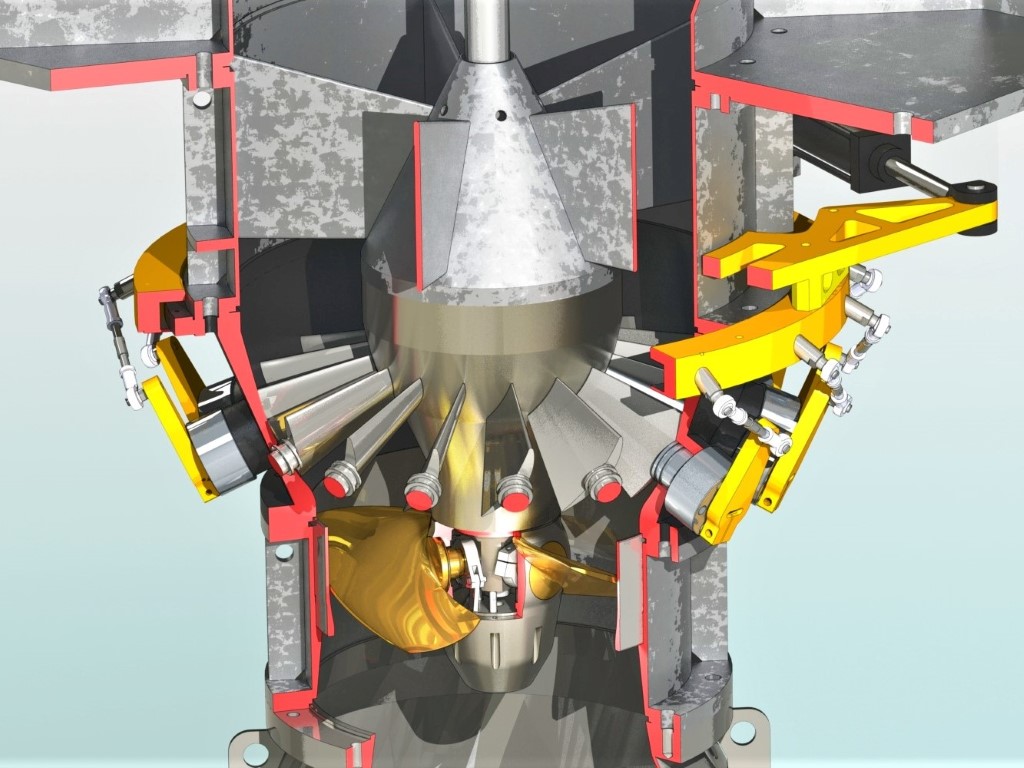

Kaplan

Kaplan turbines allow numerous applications, even in very different sectors. They are used in the presence of generally small heads and up to 50 meters. They take advantage of the large flow of the river, which can reach up to

a hundred cubic meters per second. They can be built with the vertical, horizontal or inclined axis, as well as in a dry or wet room. The construction, based on the head and the capacity, can have a fixed distributor and adjustable blades,

in this case, the turbine is of simple adjustment, also called mono-regulating. When both the distributor and the blades are variable in running, then the turbine becomes bi-regulating. With the double regulation, it is possible to obtain

greater advantages, on the capacities modulation and on the heads. In this case, the performance curve remains constant practically over almost the entire range of capacities, so as to obtain a better degree of efficiency.

Cross Flow-Banki

Cross Flow-Banki turbines are suitable for working with heads between 4 and 60 meters and are also characterized by their versatility mainly due to the special crossflow. The water enters from the upper side, crosses the impeller

axis, and comes out again from the lower side, increasing the efficiency of the turbine. The peculiar characteristics of these turbines are the simple construction and robustness, which allow a modular and low-cost construction. The water

passes through the distributor and the entrance chamber, specifically divided into a third or two-thirds, favors operation with both small and medium capacities. Under maximum capacity conditions, the turbine works with the two chambers

in parallel. The generosity and flexibility of this turbine are also determined by the uniform performance over the entire flow range.

Bulb

Bulb turbines are made from Kaplan turbines and are much simpler. They are usually used for heads of a few meters. The peculiarity of these machines lies in the bulb, immersed in water, where the alternator for energy production

is located.

Hydraulic screw

Hydraulic screws are also known as Archimedes' wheel. They invert the operating principle and take advantage from the potential difference of the falling water, from the highest point until it flows again in the course of natural water.

They are used for heads up to 10 meters and capacities up to 6 mc/s.

CONSTRUCTION

All turbines are developed and manufactured by Misa, which use its many years of experience acquired over the years, both in the design and execution of large water pumping station and in the production of electricity, for the public and private

sector. Misa also proposes all the necessary equipment for the construction of complete hydroelectric power plants, such as for example penstocks, valves, LV/MV electrical panels, automation systems, as well as remote supervision and monitoring.

In addition to what is described, MISA also offers consulting services,

analysis of hydrogeological characteristics, preliminary studies,

executive design of the whole plant, as well as management and maintenance of all the built works, including the surveillance contract. The control and supervision of the control unit takes place remotely via modem and dedicated software.

STRENGTHS

The guarantee of the Quality System according to UNI EN ISO 9001, 14001 and OHSAS 18001 standards are synonymous with professionalism and full respect for the environment.

The SOA certification in the OG9 class, category IV, “Plants for the production of electricity”, confirms a number of hydroelectric power plants built over the years, concluded with a certificate of regular execution or with

regular testing, which guarantees a high level of recognized results.

Misa is able to face any problem related to the world of energy production and water pumping in general thanks to the professionalism, passion for the environment, ideas and further special

SOA qualifications, concerning

10 different categories.

Peculiarities

The turbines produced by Misa are special customized machines, suitable for the most varied applications and with excellent performance in wide ranges of capacities and heads.

3D solid modeling, FEM structural analysis, a selected rotation speed together with the fluid dynamic study C.F.D. are the determining factors capable of guaranteeing a high quality standard, required for H24 services. Checks and tests during

the construction phases, even in the presence of the customer, optimize the installation phase, guaranteeing immediate energy production.

An Italian heart beats inside our turbines.

For more information on our axial pumps, consult the brochure or contact us directly.