Centrifugal pumps are mainly manufactured for the pumping stations where the delivery of medium capacity of water with high head, even from a considerable depth, is requested.

The absence of priming and suction problems, which is the main feature of column vertical pumps in their standard construction, and the connection to standard electric motors, always accessible, allow a great simplicity in installation and running.

When the CR or CF pumps are lowered into a basin or a pit, they are ready to run.

CONSTRUCTION

Since they are not mass-produced pumps, the construction can be suited to each specific application.

The standard construction of the MISA's CR-CF pumps series is designed for:

» installation with the pump casing submerged in the water of a tank or well;

» driven by electric motor, or, on request, to be driven by diesel engine through helical bevel gear‐box;

» column composed of flanged pipes and shafts connected by rigid couplings

» column length according to the installation as defined by the customer

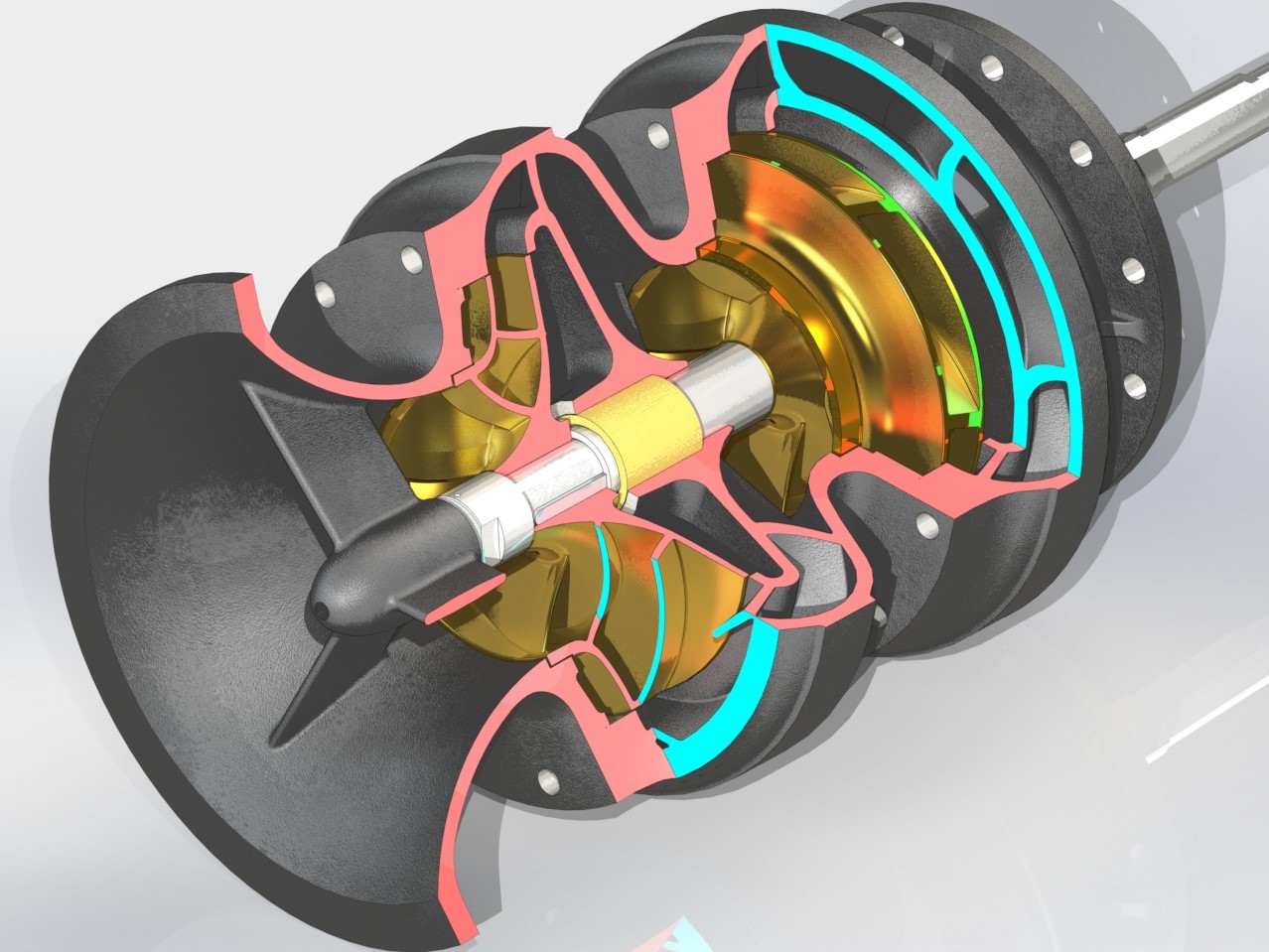

» modular pump casing, the number of the stages depends on the required head

» shaft line in contact with the pumped liquid and supported by slide bearings made of special rubber or composite material lubricated by the same liquid

The special construction of the pump casings, associated with a

ownership patterns, allows their execution in different metals and alloys, combined with the specific needs of the customer.

The quality of the product is however guaranteed by the specific production cycle through processing by CNC machine tools and, above all with intermediate checks in the stages of processing.

For further technical information, you can view our brochure.

RELIABILITY

The reliability and proper functioning of MISA's CR-CF pumps is the direct consequence of:

» Sizing and construction solutions chosen in relation to the use of the pump

» Rotation speed below the first critical speed of the shaft line for trouble-free variable speed drives

» Checks during the processing and final testing

» Care in the processing and functional checks of each single pump

Fields of application

» Civil or industrial aqueducts

» Sprinkler irrigation plants in farming and fish farming

» Land reclamation

» Filling of artificial basins in electric power plants

» Civil and industrial plants for the water treatment

» Wastewater treatment plants, desalting plants, refrigeration of thermal power plants

» Steelworks with mill scale water

» Chemical and petrochemical industries

» Fire-fighting systems

Strengths

» Adaptable to specific applications and/or customer requests

» Absence of priming and suction problems

» Maximum simplicity of installation and operation

» Reliability and durability

» Careful choice of materials based on use

» Several impellers can be mounted in series to obtain greater head

» Operation is also possible with inverters

For more information on our vertical turbine pumps, consult the brochure or contact us directly.